There are more and more new materials in home decoration. Wood plastic flooring is a new flooring material that has both the characteristics of wood and the performance of plastic. It has very good anti-corrosion performance, so it is suitable for use in relatively humid places. Let's take a look at the construction methods and precautions of wood plastic flooring.

What is wood plastic flooring?

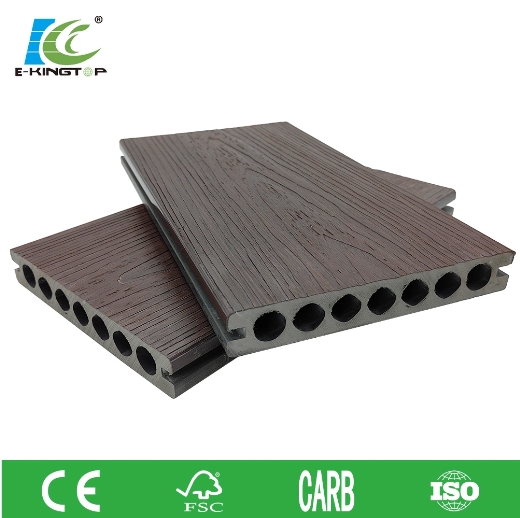

Wood plastic material is a new type of environmentally friendly and energy-saving composite material. Compared with logs, it has obvious advantages. It is mainly made of wood (wood cellulose, plant cellulose) as the basic material and thermoplastic polymer materials (PE plastics) and processing aids. After mixing evenly, it is heated and extruded by mold equipment. Because of its physical properties, it is often called a green and environmentally friendly high-tech material.

Compared with logs, it has the following advantages: more excellent physical properties (good stability, no nodes, no cracks), slightly better processing performance (smooth surface, no need for grinding), light weight, fireproof and waterproof.

Installation method of wood plastic floor

First, before installing wood plastic floor

1. From the professional perspective of installing the floor, before starting the installation work, the floor must be kept dry, flat, and clean, so as to better ensure the smooth progress of the subsequent installation work.

2. Prepare installation tools such as electric drills, ordinary woodworking tools, labor protection gloves, stainless steel screws, etc., among which electric drills are essential tools for installing plastic wood flooring. Plastic wood flooring is relatively brittle. When fixing the floor and keel, it is necessary to use an electric drill to make holes, and then insert screws to fix them to avoid damaging the plastic wood floor.

Second, the installation process of wood plastic floor

1. Fix the plastic wood keel: Arrange the keels evenly and lay them flat on the cement floor. It is recommended that the spacing between each keel is 30cm. Use an electric drill to make holes on the keel. The diameter of the holes should not be less than the diameter of the screws. Then screw the screws into the drilled holes and fix the keel on the cement floor. The nail heads should all be screwed into the keel and should not be exposed outside, otherwise it may cause the floor surface to be uneven.

2. Fix the first floor: Each piece of wood plastic floor has a positive and negative groove on the left and right sides. When laying the first floor, you can use woodworking tools to saw off or grind off the positive groove on the outside of the first floor, then use an electric drill to drill holes on the surface of the floor, screw in nails, and fix it on the keel.

3. Fix the second floor: clamp the positive groove of the second piece of wood plastic floor to the negative groove position of the first floor, then drill holes on the positive groove side surface of the second floor, screw in screws to fix it on the keel. The screw spacing can be controlled by the construction personnel during the installation process. It does not need to be too dense, just ensure that it is firm. The installation of the subsequent wood plastic floor is the same as the previous one, so there is no need to explain it more.

Precautions for installing plastic wood floor

1. Plastic wood can be cut, sawed, drilled, and mortised using ordinary woodworking machinery.

2. Use expansion tubes to fix the plastic wood keel on the floor. The spacing between the expansion tube fixing points is 500mm-600mm, and the screw caps are lower than the surface of the wood keel. The fixing of the wood keel needs to be relatively flat as a whole.

3. Self-tapping screws can be used to fasten plastic wood to plastic wood. Stainless steel self-tapping screws are recommended for outdoor use; self-drilling self-tapping screws should be used for plastic wood and steel plates.

4. When using self-tapping screws to fasten plastic wood to plastic wood, holes should be made first, that is, pre-drilled holes. The diameter of the pre-drilled hole should be less than 3/4 of the screw diameter.

5. When installing outdoor flooring, one screw is required between the plastic wood profile and each keel.

6. The intersection of the plastic wood flooring and the keel is fixed with a plastic clip to connect the plastic wood flooring to the keel

Post time: Jun-25-2024