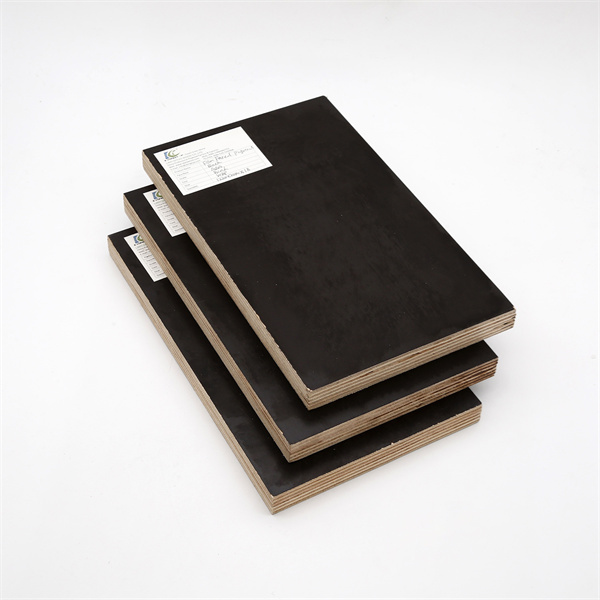

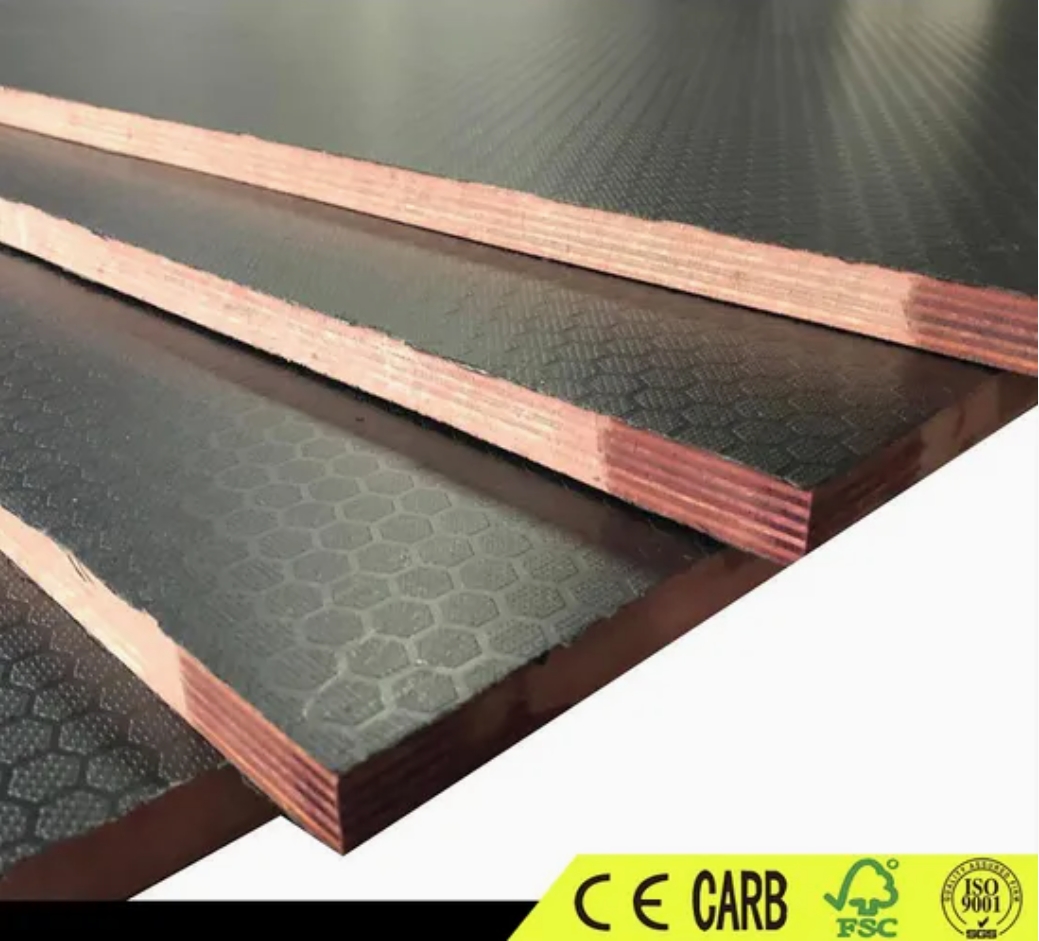

Film faced plywood has become an essential material in the construction industry, particularly for concrete formwork. This specialized plywood is designed to withstand the rigors of concrete pouring and curing, making it an ideal choice for various construction projects.

One of the primary advantages of film faced plywood is its durability. The surface is coated with a phenolic film that provides a waterproof barrier, preventing moisture from penetrating the wood. This feature not only enhances the plywood's lifespan but also ensures that the formwork maintains its structural integrity during the concrete curing process. As a result, builders can rely on film faced plywood to deliver consistent and high-quality finishes.

Another significant benefit is its ease of use. Film faced plywood is lightweight yet strong, allowing for easy handling and installation. It can be cut and shaped to fit various formwork designs, making it versatile for different construction applications. Whether for residential buildings, commercial structures, or infrastructure projects, film faced plywood adapts to the specific needs of the job.

Moreover, the smooth surface of film faced plywood minimizes the risk of surface defects in the concrete. This is crucial for achieving a polished finish, which is often a requirement in modern architectural designs. The plywood can be reused multiple times, further enhancing its cost-effectiveness and sustainability in construction practices.

In conclusion, film faced plywood is a vital component in concrete formwork construction. Its durability, ease of use, and ability to produce high-quality finishes make it a preferred choice among contractors and builders. As the construction industry continues to evolve, the demand for reliable materials like film faced plywood will undoubtedly grow, solidifying its place in modern construction methodologies.

Post time: Oct-15-2024