Combi Core Film Faced Plywood Profile-LINYI DITUO

Combi Hardwood Core Film Faced Plywood details production description

The full hardwood core film faced plywood is the best quality plywood of the LINYI DITUO WOOD.The full hardwood core film faced plywood is made of full HARDWOOD veneer.The full hardwood core film faced plywood has high density, high hardness and can be reused 10-20 times. It is the highest quality on the market.

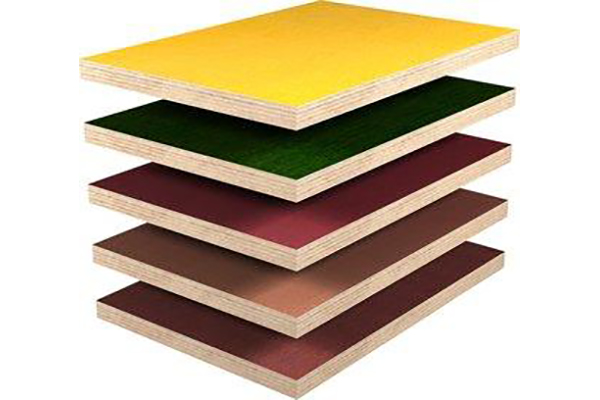

There are four types of Film Faced Plywood produced by E-KINGTOP, with brand EKINGTOP FIVE STAR (FULL HARDWOOD CORE),EKINGTOP FOUR START (POPLAR AND HARDWOOD COMBI CORE),EKINGTOP 3 STAR (FULL NEW FRESH POPLAR CORE) and EKINGTOP 2 STAR (RECYCLE CORE) respectively.These Four Types of Film Faced Plywood correspond to different grades and prices. Each Type of Film Faced Plywood has its own unique characteristics and usage occasions. Customers can choose different plywood according to their needs.

Combi Core Film Faced Plywood features

Product Name:FULL HARDWOOD Core Film Faced Plywood

Core Species:Name:FULL HARDWOOD Core Veneer .

Film:Brown,Black,Red,Green,and so on.

Glue:WBP PHENOLIC

FULL HARDWOOD Core Film Faced Plywood Can be About 15-30 times repeated using times according to formwork application projects.

Product Description

| Product: | FILM FACED PLYWOOD | Core species: | Combi | |||

| Film Color: | DYNEA BROWN,China brown,Black, Red | Grammage: | 120g/㎡,220g/㎡, 240g/㎡ | |||

| Surface treatment | Smooth, Antislip ,Wiremeshed, the wiremeshed design can be square, cross, diamond | |||||

| Size: | 18mmx1220x2440 , can also be 610*2440mm, 1200*2400mm,1250*2500mm,915*1830mm | Glue: | WBP Phenolic,WBP Melamine | |||

| Thickness | Regular thickness 9mm, 12mm, 15mm, 18mm, 21mm, can be produced as required . | |||||

| Sr. No. | Property | Unit | Standard | Value of Test | Result | |

| ⒈ | Moisture Content | % | EN 322 | 8% | Pass | |

| ⒉ | Density | kg/cbm | EN 323 | 600 | Pass | |

| ⒊ | Glue Bonding Strength | Bonding Strength value | Mpa | EN 314 | Max: 3.59 | Pass |

| Min: 2.88 | ||||||

| Wood failuere/Damage Rate | % | _ | 95% | |||

| ⒋ | Modules of Elasticity | Longitudinal | Mpa | EN 310 | 8418 | Pass |

| Lateral | 6406 | |||||

| ⒌ | Bending strength | Longitudinal | Mpa | 66.62 | Pass | |

| Lateral | 53.88 | |||||

| ⒍ | Cycle Life | 10- 20 repeated using times decided by the usage(Cleaning and storing after each time usage) | ||||

Application of Eking-top Film faced plywood

Film faced plywood used popularly as shuttering panel or formwork panel in building . It is used in concrete formwork .

The wiremeshed film faced plywood are used for scaffolding board or trailer flooring board in Europe

Advantage of Eking-top Film faced plywood

1)Good raw materials and high quality finished products,advanced production machine,experienced manufacturers .

2)More repeated using times

3)Good packing and fast shipment

4)Delivery the right products according to different requirements

5)Competitive price

6)Professional quality control team, responsible for the after-sale service

Brand Packing